The design and construction of the MEP system play a crucial role as they directly impact the operational activities of the project. Nowadays, investors are all seeking a cost-effective solution for designing and constructing electromechanical systems while ensuring efficiency. In this article, Phan Vu Engineering will share the process of designing and constructing a safe, cost-effective, and efficient electromechanical system, a solution that we have developed over many years of experience in implementing projects of various scales.

What is the electromechanical system?

The electromechanical system or M&E system (Mechanical and Electrical) is a utility that provides mechanical and electrical services for the necessary areas and equipment of a construction project. For each project, the electromechanical system plays a crucial role, accounting for approximately 30-50% (even up to 70-80%) of the entire construction project.

The electromechanical system is divided into two main components: the mechanical part and the electrical part.

Mechanical Part

- Water Supply and Drainage System: Includes water supply, drainage, and wastewater treatment systems.

- Heating, Ventilation, and Air Conditioning (HVAC) System:

- Heating: Provides warmth to the building.

- Ventilation: Manages air circulation.

- Air Conditioning: Controls and adjusts air temperature.

- Fire Protection and Fighting System (PCCC):

- Fire Alarm System: Detects and signals the presence of fire.

- Fire Fighting System: Includes equipment for firefighting.

4. Central Gas System: Manages the distribution and use of gas within the facility.

Electrical Part

- Power System:

- Dynamic Electrical System: Manages the dynamic electrical components.

- Lighting and Low Voltage System:

- Surveillance Cameras: Monitoring system.

- Telephone Exchange: Communication system.

- Computer Network: Manages the building’s network.

- Building Management System: Smart building management.

- Cable TV, Satellite, Internet: Entertainment and communication systems.

- Elevator System: Controls the building’s elevators.

- Control System for HVAC Devices, Fire and Explosion Detection: Monitors and controls ventilation devices, detects fire and explosion risks, serves the communication information system of the project.

- Generator and Backup Power System:

- Generator: Provides backup power.

- Oil Tank, Oil Pump System, Oil Pipeline, ATS Cabinet, Synchronization Cabinet: Components for managing backup power.

- Backup Battery System: Utilizes reserve batteries.

4. Lighting System:

-

- General Lighting System: Lighting for daily activities.

- Production Lighting System: Lighting for business operations.

- Artistic Lighting System: Decorative and advertising lighting.

- Emergency Lighting System and Directional Lighting System: For emergencies and guidance

5. Lightning Protection and Grounding System.

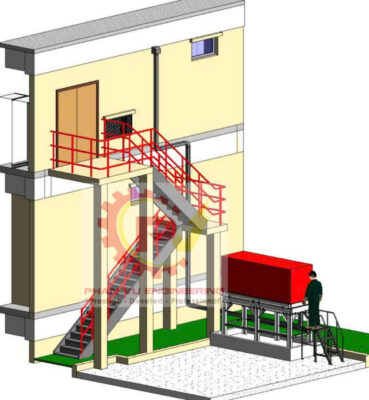

Design and Construction Process of Mechanical and Electrical Systems

To ensure the safe and timely installation of mechanical and electrical systems while maintaining quality, the construction unit must adhere to the standard design and construction process, consisting of 5 steps as follows:

Step 1: Receive Requests, Survey, and Consult Solutions

After receiving the request from the investor, the construction unit will collect information and survey the actual conditions at the site.

The survey helps the construction unit understand the scale, structure, construction conditions, installation positions of the existing systems, as well as grasp the needs and purposes of the project. Based on the collected information, the construction unit will calculate and propose specific solutions that align with the investor’s requirements, ensuring aesthetics, convenience, and safety.

From here, the investor and the construction unit will discuss, evaluate, and choose a final solution together.

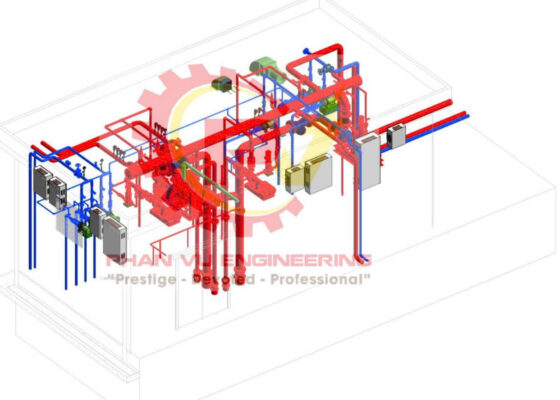

Step 2: Design Mechanical and Electrical System Drawings

Immediately after completing the site survey, the construction unit will proceed to design the mechanical and electrical systems.

The design drawings serve to help the construction unit control the progress and tasks to be implemented in each specific stage of the construction process. For the investor, these drawings provide a clear visualization of how the mechanical and electrical systems will be implemented, along with the specific installation costs for these systems.

The design drawings for mechanical and electrical systems must meet the following requirements:

- Comply with the general standards of technical drawings.

- Ensure electrical safety throughout the construction and operation of the system.

- Commit to the operational capabilities to meet the business entity’s requirements.

- Optimize and minimize costs.

The construction unit will send the design drawings to the investor for approval. After checking and reviewing the efficiency and costs, the investor will finalize the design with the construction unit for implementation.

Step 3: Construction of Mechanical and Electrical Systems

The construction and installation of mechanical and electrical systems constitute the most crucial phase of the entire process. Before commencement, all engineers involved must be briefed on the project’s characteristics and conditions and thoroughly understand the system installation diagrams.

During the construction process, the executing unit must ensure that the construction of the mechanical and electrical systems aligns with the approved design drawings. Each area requires management and supervising engineers to assign tasks and control each construction stage according to technical specifications and adherence to the initial design.

The effectiveness of the construction process is measured by accuracy, safety, cost-effectiveness, and the ease of maintaining the system in the future.

Step 4: Inspection, Training, and Commissioning of the System

In this phase, the construction unit will conduct trial runs to test whether the mechanical and electrical systems operate at the initially calculated capacity.

Once the system is confirmed to be stable and safe through testing, the construction unit will hand over the equipment documentation and payment contracts to the investor. Simultaneously, the construction unit will provide training and guidance to the investor on using the equipment to ensure the smooth operation of the entire mechanical and electrical system within the project.

Step 5: Periodic Maintenance According to the Initial Commitments

The final step in the design and construction process of mechanical and electrical systems is periodic maintenance according to the initial commitments.

Regularly inspecting the mechanical and electrical systems helps quickly identify issues, allowing for timely repairs and equipment replacements to ensure the system remains in a safe and stable condition. Additionally, this practice helps extend the lifespan of the mechanical and electrical system components.